We have expertise in Twin Lobe Roots Blower, Mechanical Vacuum Booster, Cement Feeding Systems, Cement Feeding Pumps and related systems of various pressure and vacuum applications.

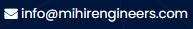

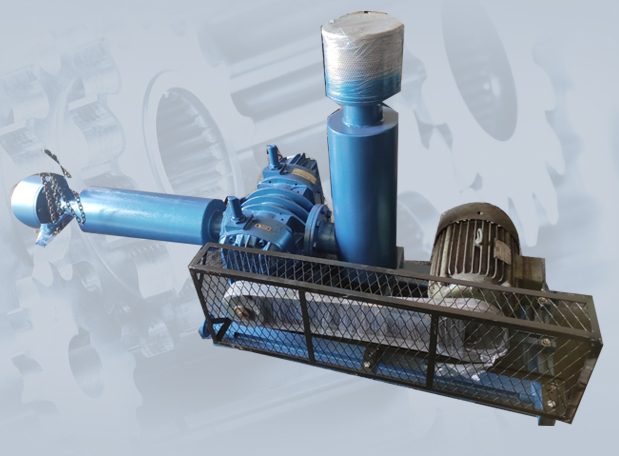

Twin Lobe Roots Blower

The Twin Lobe Roots Blower, also known as a Positive Displacement Blower, is a type of mechanical device used to move air or gas by using a pair of meshing lobed rotors that rotate in opposite directions within a housing. It falls under the category of positive displacement machines, meaning that a fixed volume of fluid (in this case, air or gas) is trapped and moved from the inlet to the outlet with each rotation of the lobed rotors.

Twin Lobe Roots Blowers are known for their simple and robust design, and they are often used in applications where a constant flow of air or gas at a relatively low pressure is required. Some common uses of Twin Lobe Roots Blowers include aeration in wastewater treatment plants, pneumatic conveying systems, vacuum applications, and in some industrial processes where a consistent flow of air or gas is necessary.

It's worth noting that while Twin Lobe Roots Blowers can provide a relatively high flow rate of air or gas, they might not be suitable for applications requiring high levels of compression or very precise control over pressure. For such applications, other types of compressors or blowers, such as screw compressors or centrifugal blowers, might be more appropriate.

Special Features of Twin Lobe Roots Blower

• Machines are air cooled, hence water cooling is not required.

• Positive displacement machine with constant volume characteristic.

• Effective sealing ensured by means of temperature- insensitive labyrinth system.

• High precision helical timing gears for reliability and long life.

• Overhung V-Belt drive for all operating pressure ranges. Direct Coupling also possible.

• Dynamically balanced rotating components to ensure vibration free operation.

• Suitable for various gasses such as air, town gas, natural gas, nitrogen gas, carbon dioxide, insert gasses.

• Solid noise-absorbing Construction in gray cast iron.

• Special air filters are provided depending upon the application and working environment.

Twin Lobe Roots Blower Application Industries

1. Wastewater Treatment: Twin Lobe Roots Blowers are used to provide aeration for the biological treatment process, where microorganisms break down organic matter. These blowers supply air to the aeration basins and help maintain the optimal environment for efficient treatment.

2. Pneumatic Conveying: In industries where bulk materials need to be transported through pipelines or conveyors, twin lobe roots blowers can be used to generate the necessary airflow for pneumatic conveying.

3. Chemical and Petrochemical: These blowers are used in various chemical and petrochemical processes. They can provide process air, assist in combustion processes, and contribute to various reactions requiring a controlled air supply.

4. Food and Beverage: In the food industry, Twin Lobe Roots Blowers are used for drying, cooling, vacuum packaging, and creating pressure for pneumatic conveying of food products.

5. Aquaculture: Twin lobe roots blowers can be used in aquaculture for providing aeration to fish ponds, promoting oxygen exchange for aquatic life.

6. Power Generation: They are used in power plants for combustion air supply to boilers, helping to maintain the necessary oxygen levels for efficient combustion.

9.Mining and Metals: In mining, twin lobe roots blowers can be used for pneumatic conveying of materials, aeration in smelting processes, and ventilation in confined spaces.

10. Plastics Industry: They are used for material handling and conveying in plastic processing plants.

Special Features of Twin Lobe Roots Blower

• Machines are air cooled, hence water cooling is not required.

• Positive displacement machine with constant volume characteristic.

• Effective sealing ensured by means of temperature- insensitive labyrinth system.

• High precision helical timing gears for reliability and long life.

• Overhung V-Belt drive for all operating pressure ranges. Direct Coupling also possible.

• Dynamically balanced rotating components to ensure vibration free operation.

• Suitable for various gasses such as air, town gas, natural gas, nitrogen gas, carbon dioxide, insert gasses.

• Solid noise-absorbing Construction in gray cast iron.

• Special air filters are provided depending upon the application and working environment.

Usage of Twin Lobe Roots Blowers in important industrial applications

- WASTE WATER, EFFLUENT & SEWAGE TREATMENTS

- ENVIRONMENTAL

- CEMENT PLANTS

- PNEUMATIC CONVEYING

- FOOD PROCESSING

- SUGAR PLANTS

- REFINERIES

- PAPER PLANTS

- SPONGE IRON PLANTS

- POWER PLANTS

- CHEMICALS PETROCHEMICALS

- INDUSTRIAL

Tank aeration, Digester gas processing, Bio gas boosting, Back washing of filter/ mixer beds.

Dust and fumes extraction, Air sparging, Compost aeration, Dust collection and disposal.

Conveying, Blending, Aeration & Fluidization

Fluidization and agitation, Pressure conveying of cement, sand, lime etc. Blending powdered materials. Vacuum conveying of temperature sensitive products.

Conveying grains, flour etc. Dehydration, Fermentation Process

Sulphitation process, Agitation of slurry

Sulphur recovery & dewaxing, Nitrogen boosting & Conveying, Hydro treater

Knife edge coating, Drying, Conveying & vacuum pickup

Injecting Blower

Ash conveying Fluidising

Handling corrosive gases, Gas Boosting, Circulation & evacuation, Liquid injection blowers

Vacuum boosting, Super-charging, Vacuum cleaning and drying, Oil free conveying of industrial gases, Fluid bad combustion

Environmental protection, conservation of resources, demographic change, cost efficiency, climate change - operators of municipal and industrial wastewater treatment plants are facing a wide range of challenges, which are constantly increasing. In order to meet these requirements, processes must be continuously optimised and adapted. With the appropriate know-how, the appropriate technology and smart control and regulation technology. After all, it is no longer just the pure blowers and compressors, that provide more efficiency with simultaneously increasing requirements and differentiated load requirements.

The chemical industry is completely dependent on reliable supplies of process gas. But each process is different and requires specialized machines. The solution: the efficient compressors and blowers from MIHIR ENGINEERS – proven in numerous operating environments, suited for almost all media, unrivalled in their reliability, and adaptable to individual client specifications. Can the solution really be this easy? It can!

You are looking for a compressed-air station which is specially optimized for your case of application? In addition to customised product solutions, MIHIR ENGINEERS supports you within the entire development cycle, from the conception to the implementation and commissioning of your compressed air station.

Some of the principal Features of Twin Lobe Roots Blower:

• Rugged Construction.

• Operate in overpressure up to 1000 Mbar.

• Suitable for continuous duty.

• Hardened and ground class 5 gears.

• Direct couple or V.Belt driven

• Lower specific power consumption

• Dynamically balanced rotary parts ensure vibration free running

• Operate in vacuum up to 500 Mbar.

• Oil free conveyance

Our Machinery:

• Lathe Machine - 03 Nos

• Shaping Machine - 02 Nos

• Surface Grinding Machine - 01 No

• Cylindrical Grinding Machine - 01 No

• Boring Machine - 01 No

• Radial Drilling Machine - 01 No

• Milling Machine - 01 No